3-Way Ball Valve

Sanitary Valves

Features:

- Connection type:Clamp end and Weld end

- Investment casting body and cap

- For food and general chemical service application

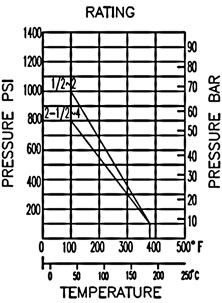

- Working Pressure:1/2” ~ 2” 1000PSI, 2-1/2” ~ 4” 800PSI

- 100% air tested under water at 100PSI, open and closed positions.

- Hydrostatic test pressure:

Body:W.P. 1000PSI

Tube end:W.P. 200PSI - Teflon encapsulated seats maintain sanitary environment.

- Blow-out proof stem and solid ball design.

- Inside Polished ≦ Ra 0.4

Options:

- Locking device is available if requested.

- Cavity filled and non-cavity filled available.

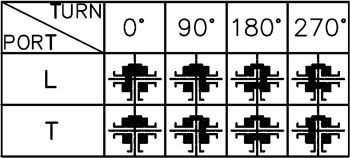

- T-Port and L-Port for choice.

Pressure-Temperature

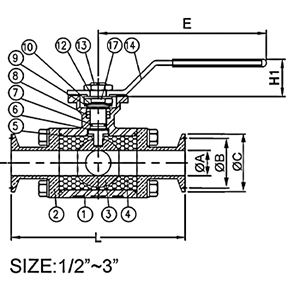

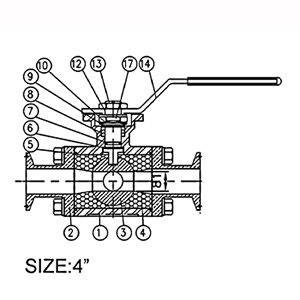

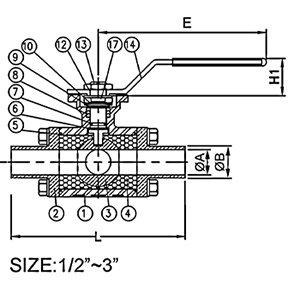

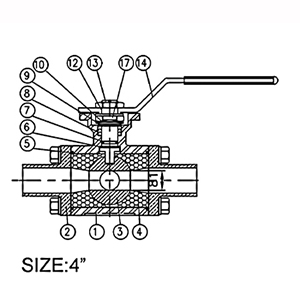

Material List

| NO. | PART NAME | MATERIAL |

|---|---|---|

| 1 | BODY | A351 CF8M / CF3M |

| 2 | CAP | A351 CF8M / CF3M |

| 3 | BALL | A351 CF8M / CF3M |

| 4 | SEAT | PTFE / TFM1600 |

| 5 | GASKET | PTFE / TFM1600 |

| 6 | THRUST WASHER | PTFE / TFM1600 |

| 7 | O-RING | VITON |

| 8 | STEM PACKING | PTFE / TFM1600 |

| 9 | RING | AISI304 |

| 10 | BEVEL WASHER | AISI304 |

| 11 | STOP PIN | AISI304 |

| 12 | NUT | AISI304 |

| 13 | STEM | AISI316 / 316L |

| 14 | HANDLE | AISI304 |

| 15 | SPRING WASHER | AISI304 |

| 16 | BOLT | AISI304 |

| 17 | PREVALING DEVICE | AISI304 |

| 18 | NUT | AISI304 |

-

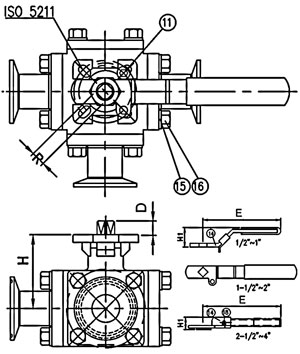

3W-40HC3-Way Ball Valve Direct Mount Clamp End

SIZE ISO-5211 ØA ØB ØC L D H H1 E R TURTEQ

INCH / LBSMM INCH 15 1/2” F03-F04 9.5 21.9 25.4 118.0 9 44.5 26 143 9 79 20 3/4” F03-F04 15.8 21.9 25.4 127.0 9 48.0 26 143 9 85 25 1” F04-F05 22.2 43.5 50.4 152.4 11 59.0 32 160 11 110 40 1-1/2” F05-F07 35.0 43.5 50.4 175.0 14 72.0 42 215 14 290 50 2” F05-F07 47.6 56.5 63.9 190.0 14 82.0 42 215 14 680 65 2-1/2” F07-F10 60.2 70.5 77.5 228.0 17 100.0 37 400 17 1060 80 3” F10-F12 73.0 83.5 90.9 260.0 23 125.5 37 400 22 1770 100 4” F10-F12 97.4 110.0 118.9 289.0 23 132.5 37 400 22 1900 -

3W-40HB3-Way Ball Valve Direct Mount Weld End

SIZE ISO-5211 ØA ØB L±1.0 D H H1 E R TURTEQ

INCH / LBS15 1/2” F03-F04 9.5 12.7 117.0 9 44.5 26 143 9 79 20 3/4” F03-F04 15.8 19.1 125.0 9 48.0 26 143 9 85 25 1” F04-F05 22.2 25.4 152.4 11 59.0 32 160 11 110 40 1-1/2” F05-F07 35.0 38.1 175.0 14 72.0 42 215 14 290 50 2” F05-F07 47.6 50.8 190.0 14 82.0 42 215 14 680 65 2-1/2” F07-F10 60.2 63.5 228.0 17 100.0 37 400 17 1060 80 3” F10-F12 73.0 76.2 260.0 23 125.5 37 400 22 1770 100 4” F10-F12 97.4 101.6 289.0 23 132.5 37 400 22 1900